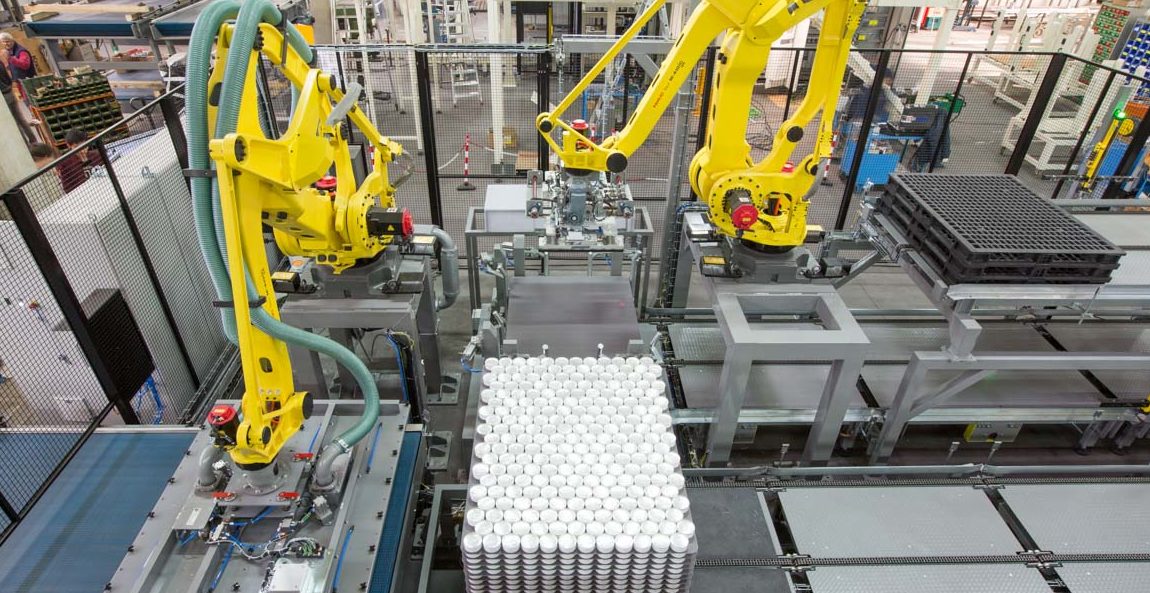

Palletizing system for loose full aluminum cans

The issue:

creating a palletizing system for loose full aluminum cans. This required the creation of the fastest machine in the world, one never before created for this application, and able to palletize almost 2200 cans, with up to 10 layers, per minute.

Palletizing system for loose full aluminum cans for a company leader in the Pet Food market

The system developed by Clevertech:

the RAP FC HURRICANE palletizer for full cans. In particular, the solution is composed of a high-speed belt conveyor for layer forming, which is able to manage approx. ten layers per minute without generating backup pressure or overlapping can edges, which would impede the pick-and-place system. Clevertech’s patented layer forming belt also incorporates a special device to prevent voids in the corners of the layer.

The layer picking system uses a robotic pick and place system with vacuum head specifically created for this application.

Moreover, two additional robots are incorporated in the system for the layer pad supply, working alternately with the main robot with a vision system to ensure correct positioning and centring of the pad on the layer.

Performance data: 2200 cans/min. 20 pallets/hour. Efficiency: 99%.