Dark Factory: an application for the Baby Care and Fem Care market

A Dark Factory is a factory which uses no human labour. This type of production site is usually completely automated, and is referred to as dark because it does not even require the workplace to be lit. In Italy, 61% of industrialists said they were ready to introduce levels of automation so high they could lead to the first Dark Factories, while in China the first companies with zero human intervention are already operational.

In Italy, the Dark Factory is seen as a way to make work safer and less strenuous, while increasing productivity and efficiency.

The Dark Factory is seen as a way to make work safer and less strenuous, while increasing productivity and efficiency

The technological innovation represented by dark factories could also have a big impact on the environment. Indeed, increased automation in industry would lead to obsolete and often polluting plants being replaced, with positive results for the planet’s health.

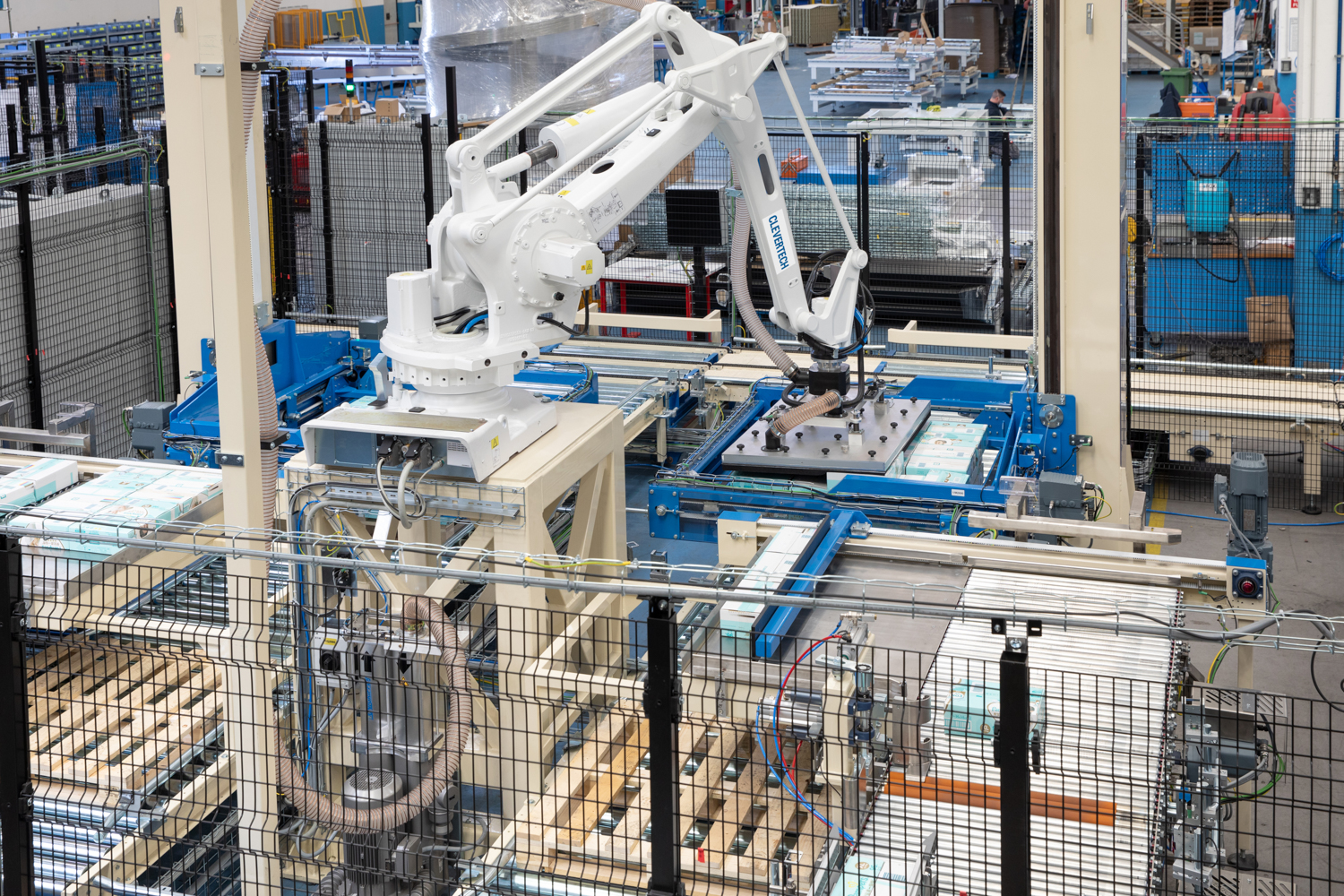

Within the scope of developing technologies for future Dark Factories, Clevertech Group has designed and created a centralised palletisation system for six production lines for a leading company in the Baby Care and Fem Care sector. The project incorporates the secondary product conveyor lines, in other words the conveyors which function as collectors, receiving and carrying the product from the production lines to a single conveyor.

Simultaneous palletisation of six products

The system guarantees performance of 80 boxes per minute. The boxes are of different weights and sizes, and are palletised using two different pallet types.

The secondary conveyors receive the products randomly, after which a series of devices such as the high-speed dividers supplied by Intralox and spiral lowerators supplied by Ambaflex transfer them from a height of around four metres to ground level, where the Clevertech system is installed. Here, the boxes are synchronised before being processed by an integrated end-of-line weight check system. In the event that the barcode and weight do not correspond, the product will be rejected.

Once the products have been processed by the weight check and barcode reading system, they are sorted into the six preforming areas. These areas allow for simultaneous palletisation of six different SKUs.

As a matter of fact, the system incorporates three RAC robots with vacuum pick-up heads. Each of these robots is responsible for simultaneous management of two SKUs.

Given the wide variety of boxes, which range from 600 mm to 200 mm, the company has installed a layer squaring system for each palletisation area, allowing perfect quality palletisation to be achieved.

Since the product managed in the system is of high added value, it is very important to preserve its quality during the individual transport and storage phases.

Automatic storage systems for Dark Factories: quality and precision

Secondarily, the squaring system is important since the Clevertech system is directly connected to an ASRS, or Automatic Storage Retrieval System. Therefore, once the pallet has been created by the palletisation robot, wrapped by an automatic wrapper, and labelled, it is transferred directly to the automatic storage system. This process occurs without any kind of manual manipulation. When the pallets enter the automatic storage system, the perfect squaring allows them to be stored without any obstruction occurring.

The centralised wrapper selected for the system is equipped with an automatic reel change system. It also features Smart Wrapping Technology which ensures the correct quantity and tension of the film at each corner of the pallet. This feature is extremely important for very light products, as well as preventing wastage, with a view to sustainability and material savings.

Complete automation at each point in the line

The supply of empty pallets is also completely automatic, as opposed to being loaded by a forklift operator. It is, in fact, the customer’s automatic storage system once again which supplies the stacks of empty pallets which feed the palletisation system, via a pallet conveyor line.

A shuttle is responsible for transferring the correct type of pallets to each of the palletisation stations. This makes the system highly flexible yet at the same time very precise, without the need for any intervention by human operatives.

The total automation was made possible by the development of the software component which allows the automatic storage system to interface with the Clevertech system.

Finally, the palletisation system is also responsible for sending the finished product to the loading station to be loaded onto trucks.