TRAINING: THE BEST WAY TO INCREASE PRODUCTIVITY

After each installation of a new palletizing and depalletizing system, Clevertech offers relevant training on the base of customer request.

Our aim is to teach and make operators more confident and independent for the use and maintenance of our systems.

A good trained operator means quick product changes, easier troubleshooting and adequate maintenance.

The training sessions (traditional class and hands on class) are studied for a max of 8 people, in order to grant the best understanding of contents to the operators.

Our trainings on palletizing and depalletizing systems can be:

- basic with PDF document

- customized with training video realized in the specific solution supplied to the customer.

They can take place on customer site or at our Headquarters.

Operator will be trained on areas such as:

- operations

- change over procedures

- adjustments

- maintenance

- safety

- HMI use

- troubleshooting

- diagnostic and spare parts

We proposes different types of training targeting for line operators, maintenance technicians, production managers, electrical and mechanical technicians.

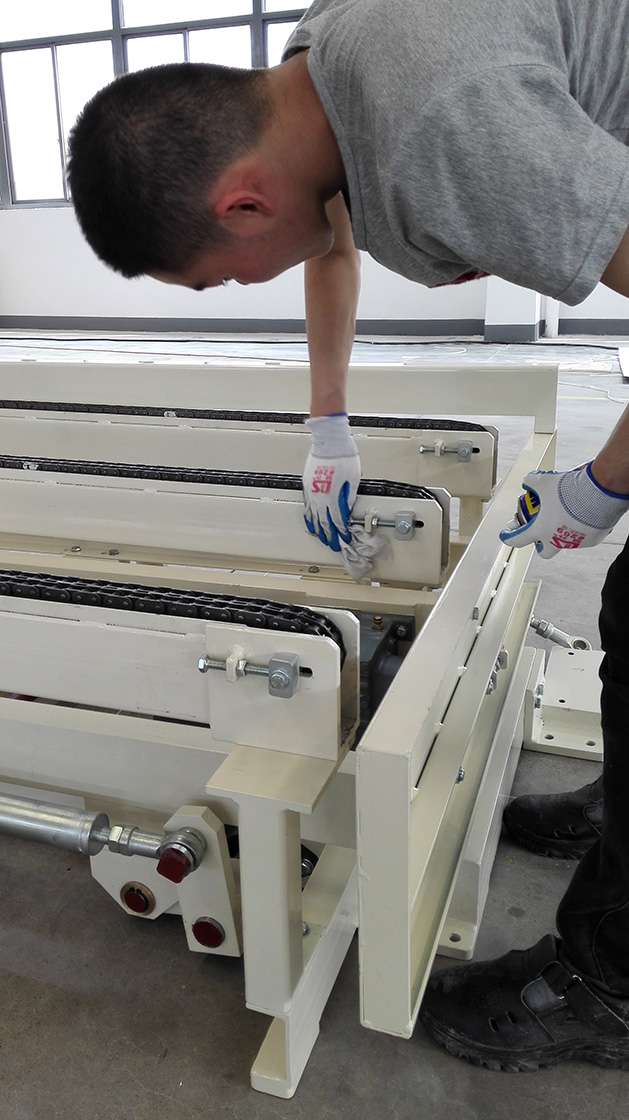

Hands on training provide real world experience, allowing the operator to get his hands on the machine.

This approach create a real sense of empowerment in the trainee and it can be more effective than just the traditional classroom.

Direct training significantly increases the productivity of our customers and it give the ownership of the equipment to the operator guaranteeing the independence of the customer in managing the line.